How the Mill Works

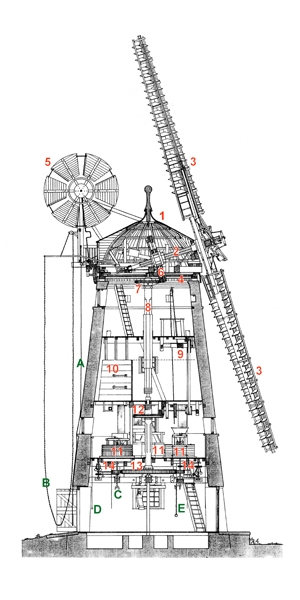

Stevens’ Mill is a tower mill, one of the three main types of windmill found in England. It is powered by four sails driven by the wind.

The tower is built from shaped blocks of clunch, a chalky stone quarried locally. It is wider at the bottom than the top, creating a tapered profile. A thick layer of lime render with a black coal tar

The tower is built from shaped blocks of clunch, a chalky stone quarried locally. It is wider at the bottom than the top, creating a tapered profile. A thick layer of lime render with a black coal tar

finish protects the stonework from damage by the elements.

Each floor of the mill has a different function:

The cap roof (1):

- Protects the building from the weather.

- Holds the cast iron windshaft (2) to which the four sails (3) are attached.

- Rotates above the curb ring (4) on top of the tower to enable the sails to face the wind.

- Is turned to face the wind automatically by the six-bladed fantail (5).

The large wooden brake wheel (6), mounted on the windshaft, transmits power to the wallower (7) at the head of the central upright shaft (8). The shaft conveys power down the mill to drive the milling machinery.

The dust (top) floor contains:

- Hatches in the floor through which sacks of grain were emptied.

The bin (second) floor contains:

- The sack hoist (9) driven by a ‘slack belt’ mechanism. This is used to haul heavy sacks of grain to the top of the mill, saving the miller a lot of effort.

- Partitioned grain bins (10) store cereals in bulk prior to milling.

The stone (first) floor is where milling takes place and contains:

- Three pairs of millstones (11) in their wooden cases or tuns. One pair has been dismantled for display.

- The crown wheel (12) mounted above head height on the upright shaft. This transmits power to the sack hoist, the flour dresser and other machinery.

The meal (ground) floor is the miller’s working area. All his controls are here:

A The brake rope starts and stops the mill.

B The striking chain opens and closes the shutters in the sails.

C Tentering screws adjust the fineness of the flour.

D Twist pegs alter the amount of grain being fed into the millstones

E The sack hoist control rope starts and stops the sack hoist.

Above head height, the great spur wheel (13) operates the millstones through smaller stone nuts. The spur wheel has 138 wooden cogs and each stone nut has 24 metal teeth. The governors (14) or ball weights adjust the fineness of the flour automatically as the sail speed changes. The engine drive shaft above the window powers the mill when there is no wind.

Beneath the raised wooden ground floor is a deep basement which can be seen through the three trap doors. The foundations and floor surface of a previous windmill were found when the basement was excavated in 2013.